Our Products

Heavy-Duty Industrial Processing & Automation Products For Meeting Every

Industrial Need With Precision!

Most Popular Products

Know More About Us

What Quality Means to Us

Ours is a company that is committed to ensuring high quality standards.

So, we implement our effectual quality controlling mechanism

in order to fabricate the impeccable assortment of Industrial...

Infrastructure

Mentioned below are the notable arrangements

that depict our adequate and sound infrastructural set-up:

A sophisticated production unit, is a real amalgamation of...

Clients' Contentment

With the motto to serve the esteemed clients with 100% client satisfaction,

we provide them with the best quality Chemical Process Tank,

Chemical Storage Tanks, etc. Our team of experienced engineers...

We mainly deal in Maharashtra, Andhra Pradesh, Tamil Nadu, Punjab and Karnataka.

About Us

When cutting-edge technologies are combined with innovative engineering

as well as product development concepts, a novel product is rolled out.

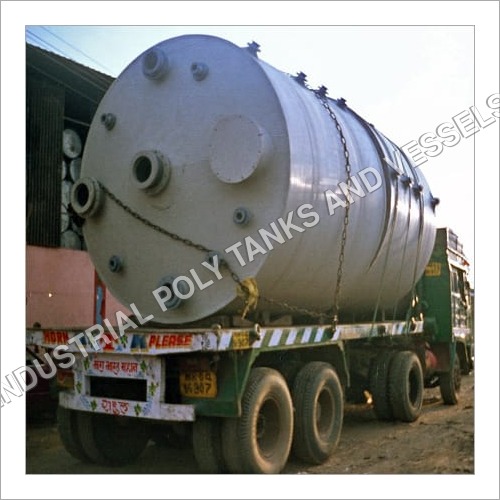

Believing in the same philosophy, Industrial Poly Tanks And Vessels

brings forth an unmatched range of Chemical Storage Tanks, HDPE Spiral Tanks,

Industrial Process Equipment, Industrial Automation Products, etc.

The company has become a leader in the domain of Industrial Processing & Automation

Products industry with its more than two & a half decades of industrial experience.

With excellence in engineering and automation,

we have become a trusted Manufacturer, Supplier and Service Provider of

high-quality products reckoned in the market for maximum efficacy and output.

Request A Quote

Please take a quick moment to complete this form

and a business representative will get back to you swiftly

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese